In today’s fast-paced industrial environment, precision, efficiency, and flexibility are crucial. Vertical Injection Molding Machines have become a preferred solution for manufacturers who need high accuracy and reliable performance in producing plastic components. At JK Machines, we provide state-of-the-art Vertical Injection Molding Machines designed to support a wide range of industries, from automotive and electronics to medical and consumer goods.

With their vertical clamping and injection design, these machines save space, ensure better insert molding, and improve overall production quality. Whether you are manufacturing small parts or complex components, our Vertical Injection Molding Machines offer the technology and reliability your business needs.

JK Machines offers a wide range of Vertical Injection Molding Machines to match different production needs:

Single-Station Vertical Injection Molding Machines – Ideal for standard production requirements.

Rotary Table Vertical Injection Molding Machines – Designed for higher efficiency, allowing mold loading and unloading simultaneously.

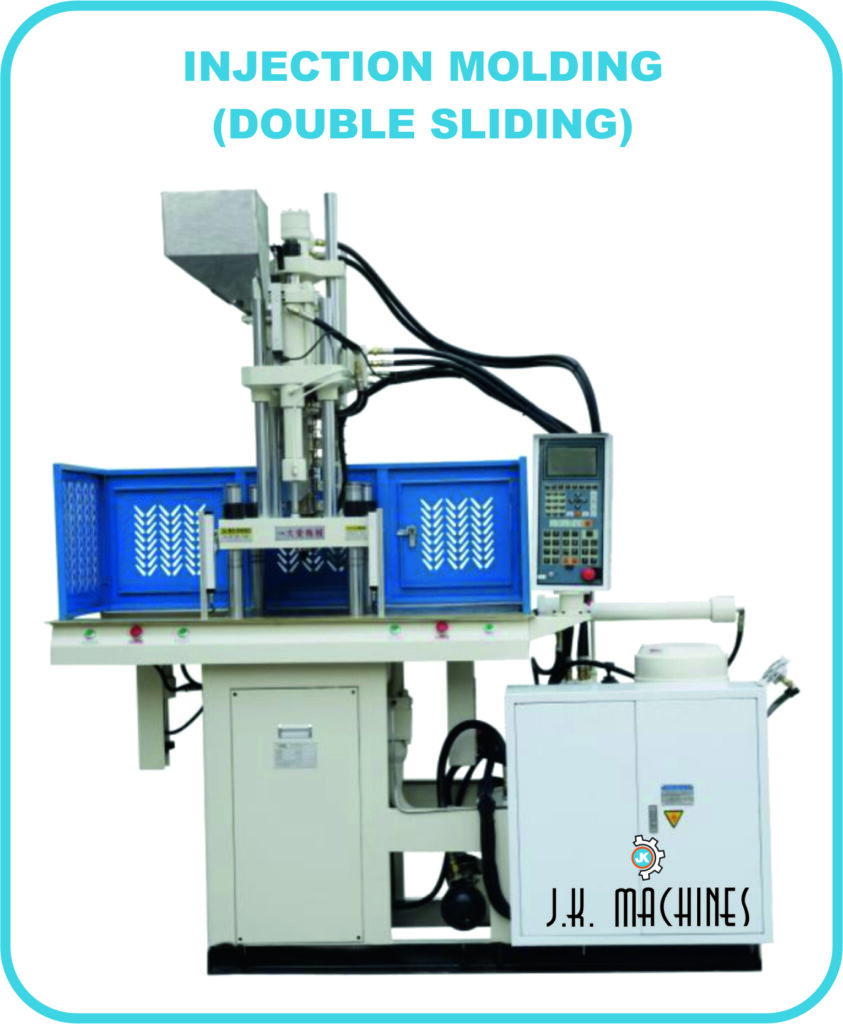

Slide-Type Vertical Injection Molding Machines – Suitable for insert and overmolding applications.

Hybrid Vertical Injection Molding Machines – Combining energy efficiency with advanced control for high-volume production

Vertical Injection Molding is a process where molten plastic material is injected into a mold cavity using a vertically oriented machine. Unlike horizontal machines, vertical injection systems use gravity to assist the process, allowing easy insert placement and better part accuracy.

These machines are ideal for:

Insert molding of metal or electronic components

Overmolding different plastic materials

Producing compact and intricate parts

The vertical design not only saves floor space but also offers superior ergonomics for operators, making it a smart choice for industries with limited space and specialized requirements.

When you choose Vertical Injection Molding Machines, you benefit from:

Efficient Use of Space: Vertical design requires minimal floor space.

Superior Insert Molding: Gravity-assisted insert placement ensures better results.

Flexibility: Suitable for both small and large production runs.

Cost-Effective: Reduced cycle times and energy efficiency lower operational costs.

At JK Machines, we are committed to delivering high-performance machinery that empowers industries to achieve more. Our Vertical Injection Molding Machines are trusted for:

Advanced Technology – Equipped with precision control systems for consistent results.

Durability – Built with high-quality components for long-lasting performance.

Customization – Machines tailored to your specific production needs.

Expert Support – From installation to training and after-sales service, we are your reliable partner.

Competitive Pricing – Offering world-class machines at affordable rates.

The growing demand for precision, efficiency, and flexibility has made Vertical Injection Molding Machines an essential part of modern manufacturing. Their unique vertical design not only saves valuable floor space but also ensures better insert molding and superior product accuracy. From automotive and electronics to medical and consumer goods, these machines play a vital role in creating products that meet global standards.

At JK Machines, we pride ourselves on delivering cutting-edge solutions that empower businesses to achieve excellence. Our Vertical Injection Molding Machines combine technology, durability, and affordability, making them a smart investment for industries of all sizes. With expert guidance, installation support, and reliable after-sales service, we ensure your business runs smoothly and efficiently.

If you are looking to upgrade your production line with machines that deliver performance, precision, and long-term value, choose Vertical Injection Molding Machines from JK Machines. Contact us today to explore our range and find the perfect solution tailored to your needs.