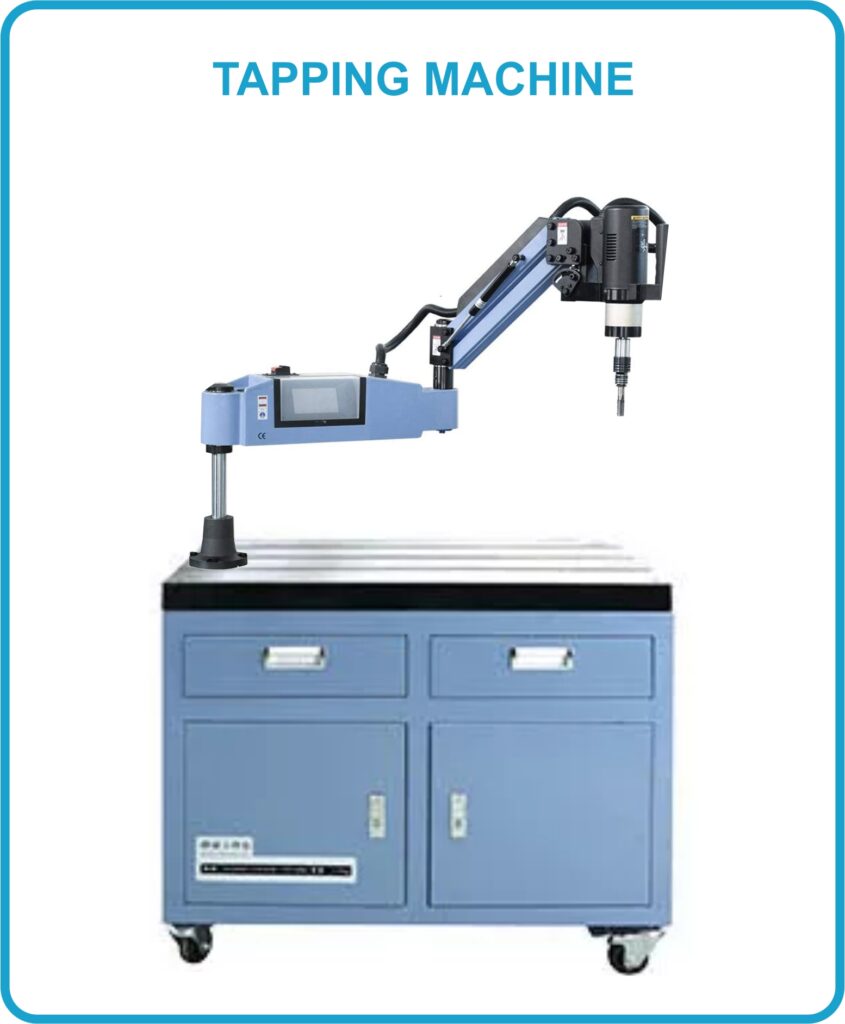

In modern manufacturing and fabrication industries, precision and efficiency play a crucial role in maintaining product quality and productivity. A Tapping Machine is a specialized tool designed to create threads inside a drilled hole, ensuring strong fastening for bolts, screws, and other components. At JK Machines, we provide advanced Tapping Machines that combine accuracy, speed, and durability to meet the growing needs of industries worldwide.

With our state-of-the-art technology and expertise, we help businesses enhance their production capabilities while reducing manual errors and downtime. If you are looking for a reliable solution for consistent threading operations, our Tapping Machines are built to deliver unmatched performance.

Our Tapping Machine are engineered for high-speed, accurate thread across a wide range of materials including metal, plastic, and alloys. Designed for both manual and automatic operations, these machines ensure consistent thread quality, fast cycle times, and minimal tool wear. Ideal for industries such as automotive, fabrication, and manufacturing, our tapping are built to boost productivity, reduce errors, and deliver long-term performance. Whether you need bench-top models or fully automatic solutions, we offer machines tailored to your exact application requirements.

Commonly used in the automobile, electronics, die & mold, and fabrication industries, our machine are built with robust materials to ensure long-term durability with low maintenance. Whether you’re tapping blind holes, through holes, or working with difficult-to-machine materials, our machines deliver fast, repeatable, and high-quality results.

In today’s competitive industrial environment, accuracy and speed cannot be compromised. Traditional threading methods are no longer sufficient for industries that require high-volume production with consistent quality.

Tapping Machines bring:

Improved operational efficiency

Minimal errors and rework

Better safety compared to manual operations

Compatibility with modern CNC and automation systems

As industries evolve, tapping machines will continue to play a critical role in manufacturing excellence.

Automotive Industry: Creating precise threads for engine blocks, gearboxes, and structural components.

Aerospace Sector: Ensuring accurate threading for high-strength, lightweight assemblies.

Electronics Manufacturing: Producing threaded parts for casings, connectors, and circuit boards.

Furniture and Woodworking: Tapping holes for screws and fasteners in wooden panels and fixtures.

JK Machines is a trusted name in industrial machinery, offering innovative solutions that cater to multiple industries. Our Tapping Machines are designed with cutting-edge technology, ensuring precision, durability, and efficiency.

What sets us apart?

Decades of expertise in supplying industrial machines

Comprehensive after-sales support, training, and maintenance

Affordable pricing without compromising on quality

A customer-first approach, ensuring every machine meets your business needs

When you partner with JK Machines, you don’t just buy equipment – you invest in reliability, performance, and long-term success.

A Tapping Machine is more than just a tool – it’s an essential asset for any industry aiming to improve production quality and efficiency. By automating the threading process, these machines save time, reduce errors, and ensure consistent results. From automotive to aerospace, electronics to woodworking, tapping machines have applications across almost every sector that relies on strong, accurate threading.

At JK Machines, we are committed to delivering world-class Tapping Machines that match the unique requirements of your industry. With our high-performance machines, expert support, and customer-focused approach, we empower businesses to achieve greater productivity and growth.

If you are ready to upgrade your production capabilities, explore our wide range of Tapping Machines and experience the perfect balance of quality, performance, and reliability. Contact JK Machines today and let us help you choose the right machine for your operations.